Project manager

Trond Olsen

E: Send email

There are many types of robots, and many probably immediately think of the classic industrial robot, which is both large, expensive, and inflexible. Norwegian industry consists mostly of small and medium-sized enterprises. For many of these, robot technology has been seen as unattainable, often due to price and complexity. Many are also probably unsure how to implement this type of technology.

The Norwegian labor market has record-low unemployment, and it is difficult to find qualified labor. At the same time, industry has great potential in automating work tasks that are largely manual, repetitive, dangerous, or ergonomically unfavorable. This is not about reducing the number of industrial jobs, but about utilizing the work capacity we have. For the industry, it is also a struggle to capture future employees. Previously, it was easier to get employees to perform repetitive tasks, while today it is difficult to recruit for such positions.

Small footprint and space: The cobot takes up little space and has built-in safety features that mean it does not have to be fenced in or take up valuable space like the larger industrial robots.

Many areas of use: The cobot can perform and take over many human work tasks that are currently manual and repetitive. This can include, for example, gluing, polishing, screwing, assembly, welding, quality control, etc.

Moved as needed: The cobot can easily be moved where it is needed. Perhaps it spends one week assembling a batch of products, while the following week it is used for polishing.

Special expertise not necessary: The cobot is easy to program, and employees can use their own creativity to find new areas of use where a cobot can create value. In addition, external expertise is easy to call in for help with more complex applications that require integration of the cobot into other systems.

Short payback time: The cobot is not particularly expensive, and it normally does not require large investments for assembly, programming, or commissioning. The payback time is approximately one year, which makes it particularly attractive for small and medium-sized enterprises.

Sustainability: Sustainable development is high on the agenda and is about both small and large measures to secure the future. It is common to think of sustainability in three dimensions: climate and environment, economy, and social conditions. Cobots undoubtedly contribute to the latter two dimensions by creating solid companies with a good working environment.

Pick-and-place

Palletizing

Grinding

Painting

Welding

Inspection

Assembly of parts

Gluing

Mounting

Operating a machine

Are you wondering how Cobots can facilitate your company’s everyday working life? Contact GA Meknett for more information.

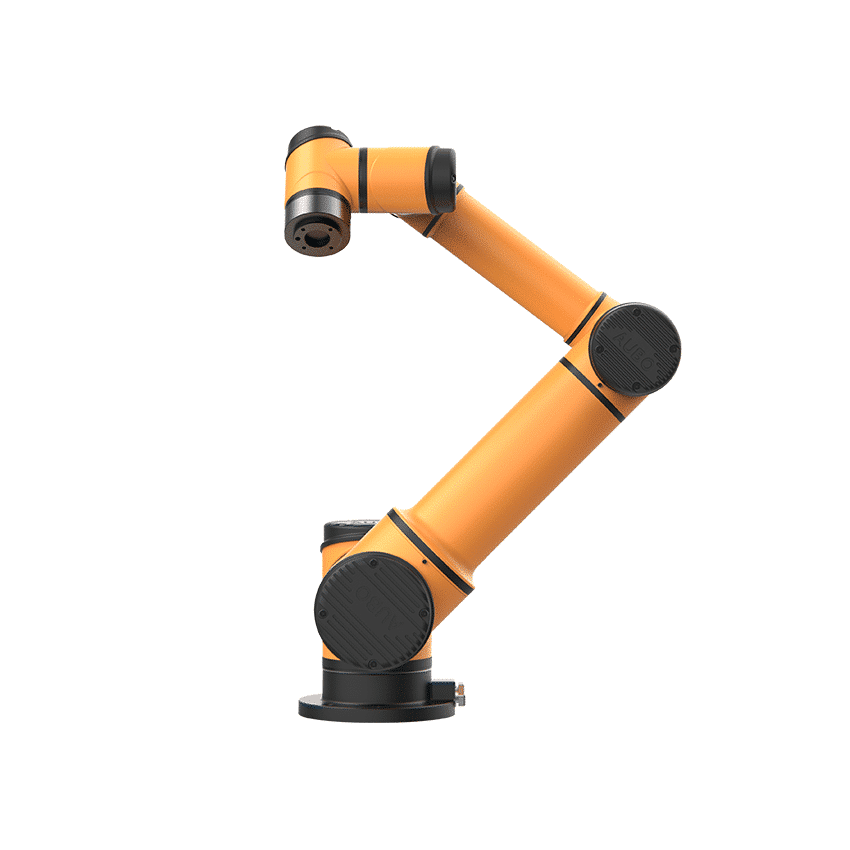

AUBO i3 Collaborative Robot (Cobot) – 3kg Payload

The AUBO Robotics i3 is a small collaborative robot (cobot) with a reach of 625 mm and a payload of 3 kg, making it ideal for a wide range of pick-and-place and assembly operations.

Payload: 3 kg

Number of axes: 6

Reach: 625 mm

Weight: 15.5 kg

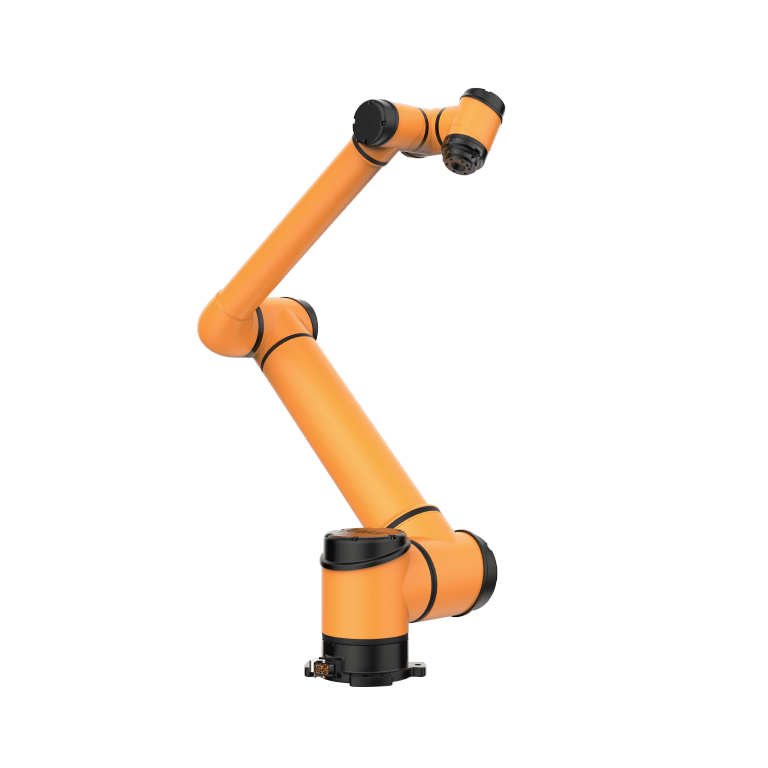

AUBO i5 Cobot – 5kg payload capacity

With a reach of 880 mm and a payload of 5 kg, the AUBO Robotics i5 is an ideal cobot for various machining tasks and pick-and-place operations. Its top speed of 2.8 m/s, repeatability of 0.03 mm, and small footprint make it a versatile collaborative robot.

Payload: 5 kg

Number of axes: 6

Reach: 880 mm

Weight: 24 kg

AUBO i10 Cobot – 10kg Payload

With a reach of 1350 mm and a payload of 10 kg, the AUBO Robotics i10 is an ideal cobot for various machining tasks, pick-and-place operations, and palletizing. Its top speed of 4.0 m/s, repeatability of 0.03 mm, and small footprint make it a versatile collaborative robot.

Payload: 10 kg

Reach: 1350 mm

Weight: 37 kg

AUBO i16 Cobot – 16kg Payload

With a reach of 967 mm and a payload of 16 kg, the AUBO Robotics i16 is a powerful cobot ideal for palletizing, pick-and-place operations, and various machining tasks.

Payload: 16 kg

Number of axes: 6

Reach: 967 mm

Weight: 38 kg

AUBO i20 Cobot – 20kg Payload

With a reach of 1650 mm and a payload of 20 kg, the AUBO Robotics i20 is an ideal cobot for demanding applications in machining, palletizing, material handling, welding, packaging, and more. Its top speed of 2.6 m/s, repeatability of 0.1 mm, and small footprint make it a versatile collaborative robot.

Payload: 20 kg

Reach: 1650 mm

Repeatability: ±0.1 mm

Weight: 63 kg (Viktig tillegg basert på søkeresultater)

Top Speed: 2.6 m/s

Complete Palletizing Solution

We offer a compact, flexible, and cost-effective palletizing solution suitable for production with high product variation or where speed requirements are not excessive. We offer two variants: Up to 10 kg weight and up to 20 kg weight (weight includes gripper weight).

The solution can be placed freestanding and requires no more space than a manual palletizing station. The palletizing solution can be easily moved with a pallet jack.

The palletizing solution comes with IPS (Intelligent Packaging Software), where operators can easily create their own palletizing patterns, pallet sizes, etc.